Newsletter - Volume 2 Issue 3

In this issue:

In this issue:

- Cooling an engine for fastest speed

- When enclosure cooling is needed

- Cooling CNC machines

- ComPact air conditioners

Featured video: SSC Tuatara Hits 295 mph in 2.3 miles

Cooling an engine for fastest speed

Sometimes it takes applying an existing technology to lead to advances.

Sometimes it takes applying an existing technology to lead to advances.

The video shows the world's fastest production car, Tuatara, making its 295 mph run at the Kennedy Space Center earlier this year. See video.

"A hypercar can be defined as the most superior and high-performance cars on the market worldwide. Only 1% of cars are hypercars".1

Under the hood in this rear engine hypercar, is a lot of technology behind this record breaking vehicle. This includes a dual water to air induction system. Water to air induction systems have been used in high performance vehicles to spray small amounts of water into an engine's combustion chamber to cool hot spots in order to increase compression and allow more complete combustion without knocking due to pre-detonation.2,3

Some of the key specifications the Tuatara sports are a coefficient of drag of 0.279, an engine that prduces up to 1,750 HP and less than 100 msec shift times in what SSC North America calls a robotized manual 7 speed transmissionn.

The engine is a twin turbo V8 and according to sources,4,5 the Tuatara can accelerate from 0 to 60 or 60 to 120 mph in less than 2.5 seconds. And that from a rear wheel drive car.

Sources:

1. https://www.howardsgroup.co.uk/news/group/what-is-a-hypercar

2. https://www.sscnorthamerica.com/model/tuatara

3. https://aermech.com/water-injection-system-in-bmw-old-technology-in-new-carsnew-in-bmwboostengines/

4. https://www.topspeed.com/cars/ssc/2019-ssc-tuatara

5. https://www.motorbiscuit.com/the-1750-hp-ssc-tuatara-may-be-the-worlds-fastest-production-car/

When enclosure cooling is needed

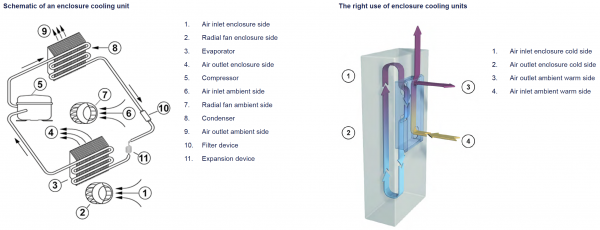

Enclosures cooling units work on the basis of a refrigeration circuit consisting of four main components; compressor, evaporator, condenser and expansion device.

The circuit is hermetically sealed and R134a refrigerant circulates inside it.

The compressor compresses the refrigerant (thus taking it to high pressure and high temperature), and pushes it through the condenser, where it is cooled by ambient air passing from the gas to the liquid state. In the liquid state it then passes through the expansion device being a much lower pressure the refrigerant arrives to the evaporator where it absorbs the necessary heat to change from liquid to gas state. The gas is then drawn back into the compressor completing the cycle.

Cooling devices are used when:

- The necessary heat dissipation can no longer take place constantly via the ambient air.

- The required temperature inside the enclosure should be the same as or lower than the ambient temperature.

- The ambient air is heavily polluted or there is increased humidity.

Product efficiency: Enclosure cooling units work according to the heat pump principle and consequently consume electrical energy. How efficiently a cooling device converts this energy into cooling performance is described by the cooling performance figure or Coefficient of Performance (COP).

The new generation of energy efficient cooling units have a COP of up to 2.5. This means that a cooling unit a rated cooling power of 2,000 W (L35L35) will only consume 800 W power (2,000 / 2.5) power.

Cooling CNC machines

A CNC machine manufacturer needed to cool their line of CNC machines. A stainless steel Seifert Systems' Thermoelectric Cooler with a 510 BTU/hr rating was selected to provide ample cooling capacity for this application, out of a range of models from 100 to 2,730 BTU/hr.

A CNC machine manufacturer needed to cool their line of CNC machines. A stainless steel Seifert Systems' Thermoelectric Cooler with a 510 BTU/hr rating was selected to provide ample cooling capacity for this application, out of a range of models from 100 to 2,730 BTU/hr.

ComPact air conditioners

The SoliTherm ComPact line has a new approach to the air conditioning of control cabinets. The condenser has a nano-coating hydrophobic treatment that makes these cooling units suitable for most industrial environments.

The SoliTherm ComPact line has a new approach to the air conditioning of control cabinets. The condenser has a nano-coating hydrophobic treatment that makes these cooling units suitable for most industrial environments.

They can also be used without filters. The high separation between fins of over 4 mm allows dust and debris to flow through. These features reduce the risk of condenser clogging, allowing long intervals between cleaning or routine maintenance operations.

Learn more about the SoliTherm ComPact Air Conditioners.

If you have a question about enclosure cooling for your specific application, Seifert Systems' technical staff would be glad to speak with you. Email us at info.us@seifertsystems.com or call 401-294-6960 .

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor