Newsletter - Volume 3 Issue 2

In this issue:

In this issue:

- New High Power Density Thermoelectric Tech

- When to Use Thermoelectric Coolers

- Cooling Telecom Cabinets

- Top-Mount Enclosure Cooling

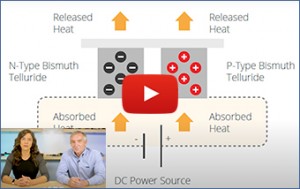

Featured video: https://www.youtube.com/watch?v=zZ8-qZGQgIY

New High Power Density Thermoelectric Tech

Scientists from the Department of Materials Science and Engineering at Pennsylvania State University and the University of Minnesota have published a technical paper and created a working thermoelectric device that demonstrated a 210% enhancement in cooling power density compared to a leading commercial devices made of bismuth telluride (Bi2Te3). At the same time, it seemed to maintain a coefficient of performance (COP) that was on par with a commercial device. COP is the ratio of useful cooling to energy required for an application.1,2

At the core of this new technology is a new process using half-Heusler (hH) alloys. According to the authors, "this study utilized Sb-pressure controlled annealing process to modulate the microstructure and point defects of Nb0.55Ta0.40Ti0.05FeSb compound, resulting in a 100% increase in carrier mobility and a maximum power factor of 78 μW cm−1 K−2, approaching the theoretical prediction for NbFeSb single crystal."

This means the process enabled more efficient electron movement in the material, leading to higher cooling density and efficiency for greater thermal conductivity.

This technology is so new, there does not appear to be a video demo of it yet. We have provided an excellent video on the basics of thermoelectric technology in its place.

Sources:

1. https://www.nature.com/articles/s41467-023-38446-0

2. https://techxplore.com/news/2023-07-high-power-thermoelectric-device-cooling-next-gen.html#:~:text=A%20new%20thermoelectric%20cooler%20developed%20by%20Penn%20State,heat%20in%20future%20high-power%20electronics%2C%20the%20researchers%20said.

When to Use Thermoelectric Coolers

The thermoelectric effect is also called the Peltier effect after its inventor Jean Charles Athanase Peltier. It is the direct conversion of temperature differences to electric voltage and vice-versa. Since the direction of heating and cooling is determined by the polarity of the applied voltage, thermoelectric devices can also be used as temperature controllers.

Peltier cooling units are mainly used for smaller power losses (100 to 2,700 BTU/hr). Unlike conventional cooling units, Peltier devices can be mounted in any position. For practical use though, condensate management should be kept in mind when deciding on mounting position. With a protection rating of IP 66 they can be used both for indoor and outdoor applications.

Applications that utilize thermoelectric coolers range from cooling integrated circuits to small camping or sports coolers for holding food and beverages to enclosure cooling for industry. Enclosure cooling applications include kiosks, data centers, ATMs, and off-highway vehicle cabin cooling.

See Thermoelectric Cooler products here.

Cooling Telecom Cabinets

Climate control of remotely located outdoor telecom cabinets requires air conditioning products that work well in harsh environments. Outdoor ambient temperatures can run over 100°F, depending on where the cabinet is geographically located. The inside of the cabinet would obviously be even hotter. In addition, since space inside the cabinet is typically taken up with 4G and/or 5G equipment, most of the air conditioner is outside and exposed to the elements.

A major telecom systems company chose Seifert's 4,000 BTU/hr Progressive cabinet air conditioners which met their applications cooling needs—even under the conditions described above.

Top-Mount Enclosure Cooling

Seifert's top mount enclosure air conditioners combine maximum cooling power with minimum space requirements. For applications where recessed or external mounting are not an option, these filterless air conditioners provide reliable cooling even under extreme industrial conditions. They are designed to ensure virtually maintenance free reliable operation. Only high quality components are used, for trouble-free operation and long life cycle.

Learn more here.

If you have a question about enclosure cooling for your specific application, Seifert Systems' technical staff would be glad to speak with you. Email us at info.us@seifertsystems.com or call 401-294-6960 .

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor