Newsletter - Volume 1 Issue 1

In this issue:

In this issue:

- Passive Cooling Device Technology

- Why Enclosures Require Cooling

- Cooling Unit Fits In Shallow Space

- Progressive Series of Air Conditioners

To view newsletter in your browser click here.

Passive Cooling Device

Passive Cooling Device

Passive Cooling Device Technology

A new passive device exists that its scientist and engineer creators say will absorb heat from inside an enclosure and "emit it to the outside"—without power. They call it the "Janus Emitter." It is made up of thin structured layers of elements that include silver and polydimethylsiloxane on a quartz substrate. According to Professor Song, who led the study, "The thermal radiation characteristics of the device allow it to function as a heat channel that efficiently draws heat from the enclosure and sends it outside."

The faces of the device have unique properties for passively cooling. For example, according to SciTechDaily, "The bottom side absorbs a broad spectrum of thermal radiation from inside the enclosure and, through a quantum phenomenon called 'spoof surface plasmon polaritons,' re-emits this energy to the atmosphere on the top side in a selective frequency range that maximizes emissivity." The bottom line is that, according to the authors, "the Janus device can passively mitigate the greenhouse effect in enclosures while offering surface cooling performance comparable to conventional radiative coolers.

Sources:

1. Science Magazine

2. SciTechDaily

3. Video

Why Enclosures Require Cooling

As control electronics, processors and servers seek to deliver more functionality and at faster speeds, more energy is used. With increasing automation of production processes more electronic components are being used. This also creates more heat. These components generate a lot of power loss which converts into heat. The increasing temperatures inside the enclosures have a negative influence on the life cycle of the components inside. If left exposed to higher temperatures for too long, thermal aging can shorted components life.4 Some components can be affected with very short exposure times too.

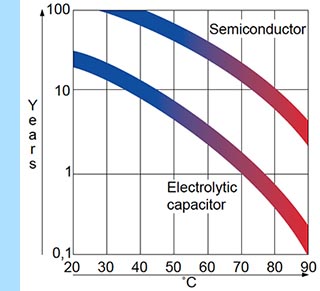

The diagram to the right shows the effects of the increased heat load on random components' Temperature vs. Component Life service life. As you can see in the diagram, as the temperature semiconductors and electrolytic capacitors are exposed to increases to over 55 degrees Celsius (131°F), electrolytic capacitors especially can fail in less than five years.

The diagram to the right shows the effects of the increased heat load on random components' Temperature vs. Component Life service life. As you can see in the diagram, as the temperature semiconductors and electrolytic capacitors are exposed to increases to over 55 degrees Celsius (131°F), electrolytic capacitors especially can fail in less than five years.

Performance of a semiconductor part can be affected before it fails, so to support reliability of electronic equipment running in an enclosure, maintaining a temperature that is within the specifications of the components used in the equipment is vital.

Ceramic capacitors, for instance, can change capacitance, their dielectric constant and have lowered insulation resistance when exposed to higher temperatures. Humidity can also have an adverse effect on electronic components. These affects include drift of value such as resistance, shorts, changes in gain, etc., depending on the type of component.5

Sources:

4. Thermal degradation of electronics.

5. Effect of temp. and humidity on components.

Cooling Unit Fits In Shallow Space

A machining center needed an air conditioning unit to integrate into their machine that would hardly protrude outside of the machine enclosure. They also needed a unit that would take up as little space as possible inside the enclosure.

A machining center needed an air conditioning unit to integrate into their machine that would hardly protrude outside of the machine enclosure. They also needed a unit that would take up as little space as possible inside the enclosure.

A shallow and slim design air conditioner that would produce over 2,700 BTU/hr of cooling power was required in this application.

With a depth of only 5.7 inches, the SlimLine cooling unit shown here integrates perfectly into the machine housing for this application. Designed for recessed installation, the cooling unit only protrudes less than one inch from the rear wall of the machine. The cooling unit used in this application is model

KG 42711001 with a cooling capacity of 2,730 BTU/hr. Many of Seifert's SlimLine air conditioners are designed to fit in an enclosure with available depth of less than six inches.

Progressive Series of Air Conditioners

Designed for indoor and outdoor use in enclosures, the Progressive line of air conditioners are specifically designed with the features and options most requested by enclosure specialists. They are drip-free, come with a two-year warrantee and feature:

Designed for indoor and outdoor use in enclosures, the Progressive line of air conditioners are specifically designed with the features and options most requested by enclosure specialists. They are drip-free, come with a two-year warrantee and feature:

• Integrated condensate evaporation

• UL listed: types 12, 4, 3R and 4X

• Powder coated or stainless steel

• Cooling cap: 1,000 to 21,000 BTU/hr

• Mounting flange for quick installs

• Easy access programmable controller

Looking for Enclosure Air Conditioners that have the same footprint? Seifert's new Progressive series now offer multiple cooling capacities with the same cutout! Simplify your inventory selection today. Seifert's 12-inch narrow design allows for all AC units up to 8,500 BTU/hr to mount on 12-inch deep enclosures! Virtually all units in stock and readily available from our Rhode Island facility.

Learn more.

If you have a question about enclosure cooling for your specific application, Seifert Systems' technical staff would be glad to speak with you. Email us at info.us@seifertsystems.com or call 401-294-6960 .

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor