Newsletter Volume 5 Issue 1

In this issue:

In this issue:

- Self-Refilling Coffee Machine

- The Uses For Thermostats and Hygrostats in Cooled Enclosures

- Determining Cooling Capacity Needed for Your Enclosure - Part I

- LED Enclosure Lights

Featured video: Turn Air Into Coffee | Kara Pod | CES 2025

Self-Refilling Coffee Machine

Enclosure cooling systems include air conditioners, heat exchangers and even small heaters. A heater is generally used to eliminate humidity and condensation problems in outdoor applications.

Some of these systems are used, though on a small scale, in the air-to-water system Kara™ Water company incorporates into their Kara Pod coffee machine. Creating up to almost a gallon of water a day from thin air the company calls this machine "the world's first self-filling coffee machine." It uses standard Nespresso* coffee pods as well as Kara Water's own biodegradable pods.

Some of these systems are used, though on a small scale, in the air-to-water system Kara™ Water company incorporates into their Kara Pod coffee machine. Creating up to almost a gallon of water a day from thin air the company calls this machine "the world's first self-filling coffee machine." It uses standard Nespresso* coffee pods as well as Kara Water's own biodegradable pods.

From a technical standpoint, here's how air-to-water systems work in general. Air is drawn in by a fan. It could be filtered at this point, then the air is cooled so that the temperature is lower than the dew point temperature, causing water droplets to form. For example, if the indoor air temperature is 72°F and the relative humidity is 50%, the dew point temperature would be 52.3°F. So a miniature air conditioner, heat exchanger or thermoelectric cooling device is needed. Next the water filtered through several filters, possibly exposure to uv light to ensure impurities, bacteria and other possible contaminants are eliminated. Then it is collected in a storage container. A miniature heater would be used to heat the water that is pumped through the coffee pod to make the coffee.

Technical specifications on the Kara Pod coffee machine include dimensions of 15 x 9 x 14 in (l x w x h), dispenses both drinking water and coffee or tea, weight is 13 lbs, power consumption is 320 W. The company projects the cost when on sale this summer will be $599.

Source:

1. https://www.youtube.com/watch?v=_Cz1qXiTbKk

2. https://launch.karapod.com/

3. https://youtu.be/iH_TRtj1Mr0?si=6Becg1NwVUiAh63B

4. https://interestingengineering.com/ces-2025/worlds-first-self-refilling-coffee-machine-kara-pod

* Nespresso is a division and property of Nestlé Nespresso S.A. / Kara is a trademark of Kara Atmospheric Water, Inc.

The Uses For Thermostats and Hygrostats in Cooled Enclosures

Thermostats and hygrostats ensure an optimal climate inside your enclosures or cabinets. Thermostats are available either as normally closed (NC) or as normally open (NO). NC thermostats are used for regulating heaters or for alarm signals when the enclosure temperature is falling below the preset minimum value. The contact opens when the temperature is rising.

Thermostats and hygrostats ensure an optimal climate inside your enclosures or cabinets. Thermostats are available either as normally closed (NC) or as normally open (NO). NC thermostats are used for regulating heaters or for alarm signals when the enclosure temperature is falling below the preset minimum value. The contact opens when the temperature is rising.

NO thermostats are used for regulating filter fans, heat exchangers, and Peltier cooling units or for switching alarm signals when the preset temperature limit has been exceeded. In addition our temperature and humidity sensors can monitor the preset parameters to ensure that failures or malfunctioning of equipment can be avoided.

Determining Cooling Capacity Needed for Your Enclosure - Part I

Determining the cooling capacity needed for each enclosure application and the type of cooling equipment best suited for those applications is the topic this newsletter is covering in the next several issues.

Determining the cooling capacity needed for each enclosure application and the type of cooling equipment best suited for those applications is the topic this newsletter is covering in the next several issues.

The factors that go into calculating the cooling capacity needed for a specific enclosure cooling application are enclosure volume, enclosure material, enclosure environment and position, enclosure location, ambient temperature, enclosure temperature, the type of cooling product, where the cooling product will be mounted on the enclosure, the voltage powering the cooling equipment and the internal heat load inside the cabinet.

Let's detail these one at a time starting with the volume inside the enclosure that needs to be cooled. The volume is readily calculated by multiplying the height, width and depth of the enclosure.

Next, the type of material the enclosure is made of affects the heat conduction inside the enclosure, so this needs to be taken into account. Common materials include mild steel, stainless steel, aluminum and plastic. The heat transfer coefficient of each of the materials is different and measured in Watts per square meter Kelvin. Obviously any enclosure cabinet measurements taken in inches would have to be converted to metric units to apply these coefficients correctly.

The environment and position of the enclosure have to be taken into account as well. This means whether the enclosure is free-standing or part of a grouping of enclosures along with taking into account if the enclosure is at the end or in a middle position as part of a group. If the enclosure is against a wall or not is an important factor in calculating the cooling capacity needed too.

One obvious factor is if the application is an indoors or outdoors. One less obvious factor is if the cooling equipment placed in the enclosure needs to be NEMA 4X. Ambient and enclosure temperature are vital factors as well.

The cooling product type or category needs to be taken into account as well. Will an air conditioner, air-to-air heat exchanger, air-to-water heat exchanger, thermoelectric cooler or fan be used to cool the enclosure?

Another factor is where the cooling product will be mounted: wall mounted and recessed, wall mounted and semi-recessed, rack mounted or top mounted. The power supply voltage of the cooling product is a factor too. Is it 12, 24 or 48 V? Is it 120, 230, 380, 400 or 460 V?

The last factor is the internal heat dissipation inside the enclosure from the other equipment. This can be measured or estimated by equipment specifications or past experience. More will be covered in future Cool Cab newsletters. Alternatively, this calculator does the calculation.

LED Enclosure Lights

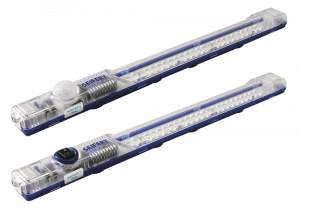

Motion Sensing and Switch Controlled LED Light Strips

Motion Sensing and Switch Controlled LED Light Strips

Our StripLite LED enclosure lights have been especially designed to meet the criteria of illuminating control cabinets. They are available with an integrated On/Off switch or motion sensor. Our 400 Lm version has a universal voltage range (24 to 265 V) with one model. The more powerful 700 Lm version has a voltage range from 120 to 230 V AC. These strip lights are designed to be daisy-chained together for additional illumination. StripLite is energy efficient and maintenance free.

For more information on StripLite LED enclosure lights, download the brochure.

If you have a question about enclosure cooling for your specific application, Seifert Systems' technical staff would be glad to speak with you. Email us at info.us@seifertsystems.com or call 401-294-6960 .

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor