Newsletter - Volume 2 Issue 1

In this issue:

In this issue:

- Analyzing Rack Enclosure Cooling Needs

- Natural vs. Forced Convection Cooling

- Kiosk Cooling

- Thermoelectric Coolers

Featured video: Design and Analysis of Data Center Rack Enclosures

Analyzing Rack Enclosure Cooling Needs

Whether they are used in data centers to hold edge computers and other Web-server related devices or for industrial uses, rack enclosures often require cooling to keep the enclosed equipment running smoothly.

Guidance on whether cooling is needed and how much cooling capacity is required can be gathered from either using a rule of thumb or for more precision, thermal analysis software.

Some companies use a general rule of thumb of roughly 45 kW of rack equipment power as a threshold for requiring direct chipset cooling.

For situations where more precise evaluation is needed, a software company called Future Facilities created the video linked to in the image and text at the top of this newsletter. The video demonstrates generally how the company's thermal analysis software can be used to evaluate specific rack enclosure types and equipment situations to predict where cooling is needed.

Sources:

1. https://www.futurefacilities.com

2. https://www.youtube.com/watch?v=sp22BQ_GqeE

Natural vs. Forced Convection Cooling

Natural Convection

If your application only has a minimal heat loss, openings in your enclosure with louvers or grills with filters can be effective enough. Usually however this method does not provide enough cooling for today‘s electronic components.

General Rules:

- Depending on the load inside the enclosure and the temperature outside, the enclosure temperature is likely to be higher than the ambient temperature.

- No moving parts — by eliminating external fans, you create a zero maintenance application.

- No dirt — utilizing exhaust filters prevents dirt

If the ambient temperature is lower than the temperature inside the enclosure, the dissipated heat escapes into the environment through the enclosure surface.

The following simple formula calculates the level of heat dissipated from the enclosure:

![]()

where,

Ps [W] = Dissipated power (thermal power dissipated from the surface area of the enclosure).

k [W/m2K] = Coefficient of heat transmission (dissipated power per 1 m2 surface area and 1 K difference in temperature). This constant is determined by the material3.

A [m2] = Surface area of the enclosure.

≜T [K] = Temperature difference between ambient air and internal enclosure air in degrees Kelvin.

3 Sheet steel - 5.5 W/m2K

Stainless steel - 5.5 W/m2K

Aluminum - 12.0 W/m2K

Plastic - 3.5 W/m2K

Forced Convection

If your installation is in a clean, non-hazardous environment with an ambient temperature less than the desired enclosure temperature, a simple forced ventilation system utilizing the ambient air is usually sufficient.

Combined with air filters, such devices generally meet the heat dissipation needs of electronic equipment.

General Rules:

- Considered rise should be at least + 10 Kelvin above ambient temperature (can vary depending on the load inside the enclosure and the ambient temperature).

- Multiple configurations possible — filter fans can be located in a number of locations within complex enclosure configurations.

- Calculate the size of a fan to include static pressure — understanding how static pressure affects the performance of a fan is very important when choosing filter fans.

The following simple formula calculates the required airflow:

where,

V [m3/h] = Air flow volume of a filter fan

PV [W] = Power loss (thermal power generated inside an enclosure by the dissipation loss of components)

≜T [K] = Temperature difference between ambient air and internal enclosure air in degrees Kelvin.

Kiosk Cooling

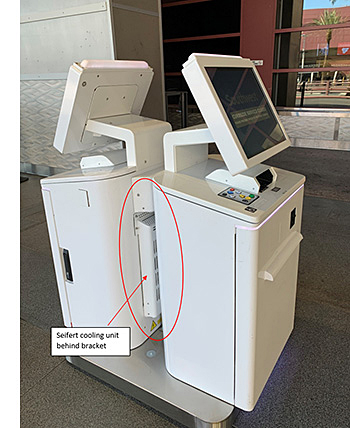

In this application, an airport kiosk required cooling for the electronic components. The problem: there was very little available space and condensate drip or tubing were out of the question for this stand-alone unit. A thermoelectric cooler solved both of these issues.

A Seifert model 3152 thermoelectric cooler supplies 510 BTU/hr of cooling capacity utilizes Peltier technology, is low profile and externally mounted. Dimensions are 15.7 x 7.1 x 6.7 in. View Seifert's complete line of thermoelectric coolers here.

Thermoelectric Coolers

|

If you have a question about enclosure cooling for your specific application, Seifert Systems' technical staff would be glad to speak with you. Email us at info.us@seifertsystems.com or call 401-294-6960 .

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor

Seifert's line of thermoelectric enclosure coolers are designed to mount in virtually any position and especially in smaller cabinets.

Seifert's line of thermoelectric enclosure coolers are designed to mount in virtually any position and especially in smaller cabinets.