Newsletter Volume 5 Issue 3

In this issue:

In this issue:

- New Thermoelectric Cooling Breakthrough

- How Enclosure Cooling Units Work

- Determining Cooling Capacity Needed for Your Enclosure - Part III

- New Progressive Air Conditioners

Featured video: New Thermoelectric Cooling Breakthrough

New Thermoelectric Cooling Breakthrough

Johns Hopkins University applied physics laboratory just released information on their new thermoelectric cooling thin-film technology called CHESS (controlled hierarchically engineered superlattice structures). They claim to have achieved double the efficiency of currently available solid state thermoelectric devices with their new nano technology based thermoelectric materials. The device level improvement was 75% and system improvement is stated to be 70%. They also relate that the new devices are not just for R & D labs but are "commercially available in bulk and easily manufacturable." This would seem to be an accurate statement based on the hybrid refrigerator in our last newsletter using this very technology.

Source:

1. https://www.sciencedaily.com/releases/2025/09/250919085242.htm

2. https://www.nature.com/articles/s41467-025-59698-y

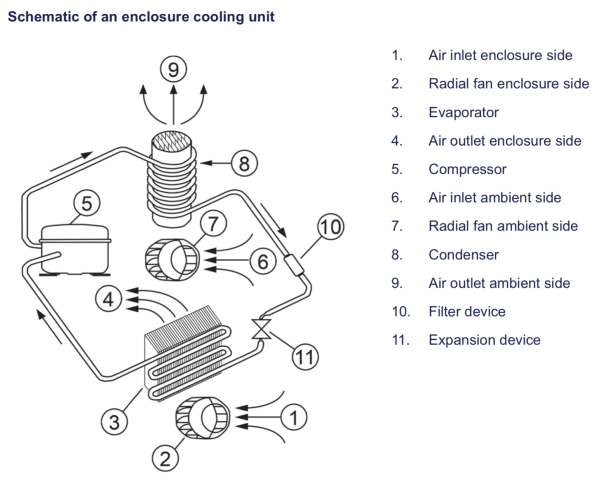

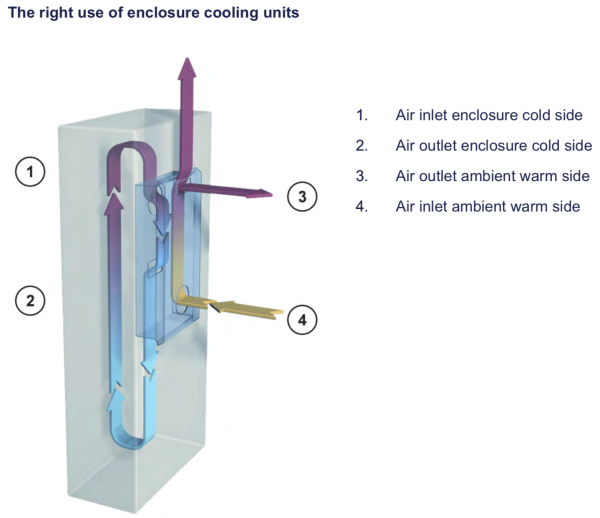

How Enclosure Cooling Units Work

Enclosures cooling units work on the basis of a refrigeration circuit consisting of four main components; compressor, evaporator, condenser and expansion device.

The circuit is hermetically sealed and R134a refrigerant circulates inside it (R134a is chlorine free and has an Ozone Destruction Potential [ODP] of 0 and a Global Warming Potential [GWP] of 1430). The refrigerant R134a can be used without restrictions according to the current regulations.

The compressor compresses the refrigerant (thus taking it to high pressure and high temperature), and pushes it through the condenser, where it is cooled by ambient air thus passing from the gas to the liquid state. At the liquid state it then passes through the expansion device being a much lower pressure the refrigerant arrives to the evaporator where it absorbs the necessary heat to change from liquid to gas state. The gas is then drawn back into the compressor completing the cycle.

Cooling devices are used when:

• The necessary heat dissipation can no longer take place constantly via the ambient air.

• The required temperature inside the enclosure should be the same as or lower than the ambient temperature.

• The ambient air is heavily polluted or there is increased humidity.

Product efficiency: Enclosure cooling units work according to the heat pump principle and consequently consume electrical energy, which is a financial expense. How efficiently a cooling device converts this energy into cooling performance is described by the cooling performance figure or Coefficient of Performance (COP).

The new generation of energy efficient cooling units have a COP of up to 2.5. This means that a cooling unit a rated cooling power of 2,000 W (L35L35) will only consume 800 W power (2,000 / 2.5) power.

Determining Cooling Capacity Needed for Your Enclosure - Part III

In the last two issues of Cool Cab News we covered an overview of what information is needed to determine the cooling capacity needed for each enclosure application and the type of cooling equipment best suited for those applications in Part I.In the last two issues of Cool Cab News we covered an overview of what information is needed to determine the cooling capacity needed for each enclosure application and the type of cooling equipment best suited for those applications in Part I.

In the last two issues of Cool Cab News we covered an overview of what information is needed to determine the cooling capacity needed for each enclosure application and the type of cooling equipment best suited for those applications in Part I.In the last two issues of Cool Cab News we covered an overview of what information is needed to determine the cooling capacity needed for each enclosure application and the type of cooling equipment best suited for those applications in Part I.

In Part II we detailed the first steps in determining your application's required cooling capacity–choosing your enclosure's parameters.

In this issue we cover the next steps to determine cooling capacity needed for your application.

Enclosure A/C This includes choosing parameters specific to your application's orientation and temperature parameters.

The next application parameter needed is location type: indoor, outdoor, 19-inch rack mounted or NEMA 4X housing.

After that, note the ambient temperature in the area around the enclosure and inside the enclosure temperature.

The calculation also depends on the type of product you intend to use to cool the enclosure. This could be an air conditioner, air to air heat exchanger, air to water heat exchanger, filter fan(s), thermoelectric cooler. Note also if an enclosure heater will be used.

Other information needed for the calculation is the mounting type: wall mounted/recessed, wall mounted/semi recessed, roof mounted, rack mounted or rail/screw mounted. The power supply voltage to the cooling unit also needs to be considered.

Finally, the measured or estimated power dissipation (heat load) inside the cabinet needs to be factored in.

Alternatively, this calculator does the entire calculation.

New Progressive Air Conditioners

Progressive SeriesProgressive Series

Progressive SeriesProgressive Series

Advanced Enclosure Air Conditioners

The Progressive Series is uniquely designed with these user preferred features:

• Power Coated Steel – RAL 7035 and Stainless Steel

• Modbus RS485 interface

• Integrated Heater

• Aluminum mesh filter

• R134a refrigerant

• Digital programmable controller

• Controller default set to 95°F to cool – adjustable 68°F to 122°F

• High temp alarm preset to 131°F

• Operating temperature range -40°F to 140°F

• Cage clamp terminal connector

Every Progressive air conditioner comes with an integrated condensate evaporation package that is designed for drip-free operation. The digital controller with built-in display is viewable and accessible from inside the cabinet. A mounting flange allows for quick and easy installation.

View Progressive models' performance curves, specifications and download data sheets and CAD drawing files here.

If you have a question about enclosure cooling for your specific application, Seifert Systems' technical staff would be glad to speak with you. Email us at info.us@seifertsystems.com or call 401-294-6960 .

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor